Wire Rod Mill

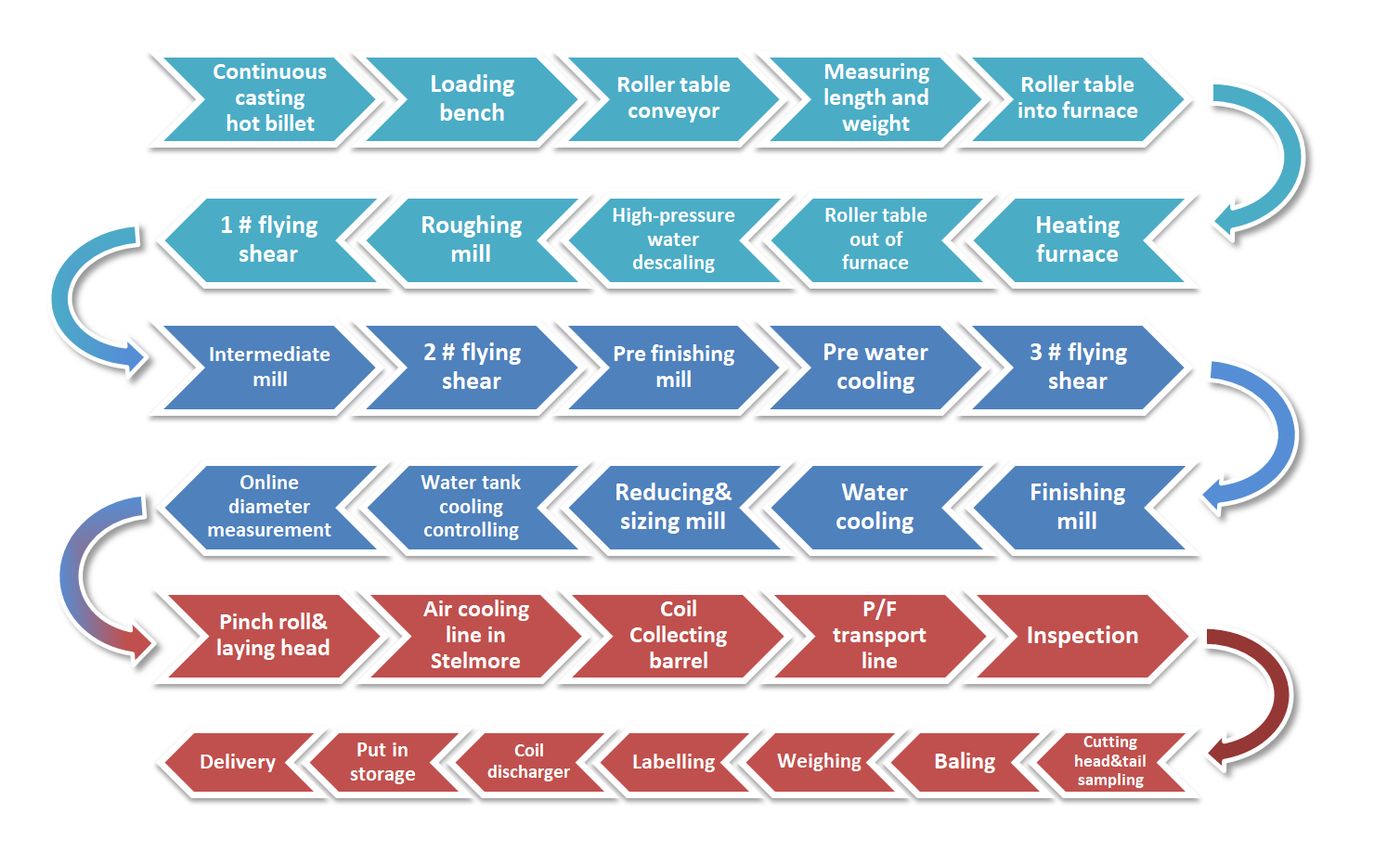

Modern production should adopt new types of roughing and intermediate rolling mills, cantilever non-twisting pre-finishing rolling mills, super-heavy top-crossing 45° non-twisting finishing rolling mills and set start-stop flying shears and water cooling devices, and use sizing and reducing mills to implement precision Rolling, as well as equipped with online caliper and online flaw detector, and the use of a new laying machine.

roughing and intermediate mills

roughing mill layout

The H&V convertible stands are all housingless mills and 4 rows of rolls centripetal bearings are adopted, which can bear the rolling pressure in all aspects. All parts and components of the rolling mill can be interchanged to reduce the reserve quantity of spare parts.

Pre-Finishing Mills

Pre-Finishing Mill layout

The pre finishing rolling mills are cantilever rolling mills. The four stands are divided into two horizontal and two vertical rolling mills. There are three vertical loopers and a safety cover. The arrangement mode is H-V-H-V, which is separately driven by DC motor.

Finishing Mills

Finishing Mill layout

This top crossing 45 ° high-speed wire rod finishing mill is arranged in the high-speed wire rod production workshop. Through the continuous micro tension rolling of the 10 stands of finishing mills, the rolled pieces of Ø 17 ~ Ø 21mm conveyed by the upstream mill are rolled into finished wires of Ø 5.5 ~ Ø 16mm. The guaranteed outlet speed of the unit is 90m / s.

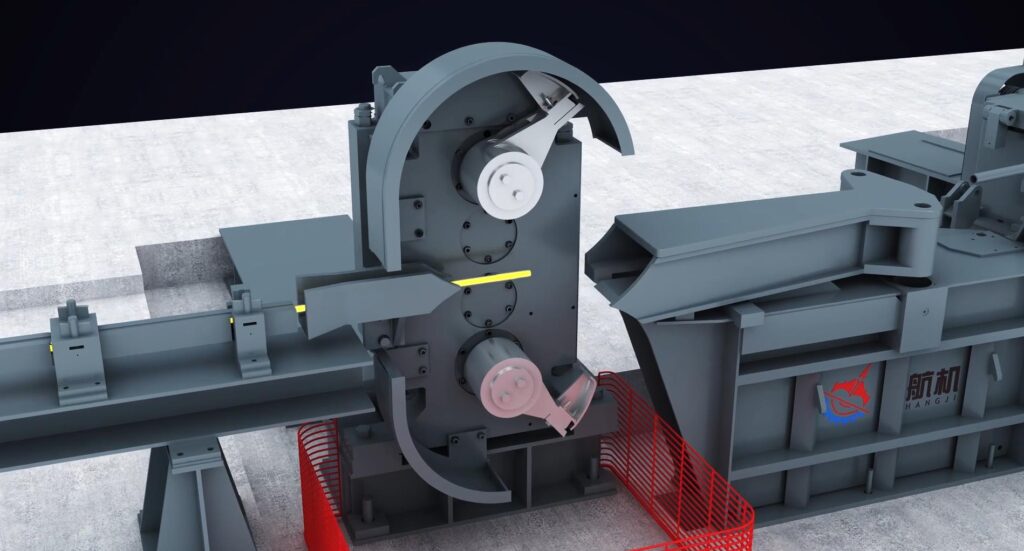

Shearing Equipment

Shearing Equipment

Shearing Equipment Includes Flying Shear, Broken Shear, Side Looper (Before Finishing Rolling), Snap Shear, Switch, Etc

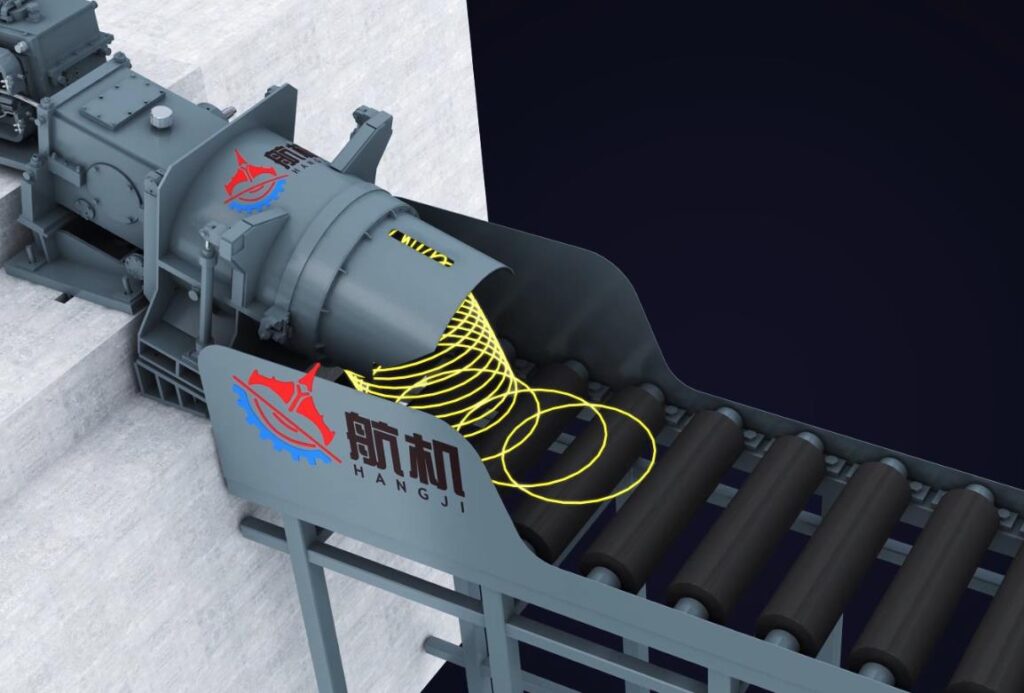

Laying Head And Pinch Roll

The Transmission Gear Box Of The LAYING Machine Is Of Welded Structure, The Gears And Bearings In The Box Are Lubricated With Thin Oil, And The Spinning Head Is Covered In The Safety Cover Of The Spinning Machine.

important things you should know

Questions And Answers

We are a professional rolling mill manufacturer with 24 years of experience supported by the chinese government. We offer tailor made high speed wire rod and bar hot rolling mill product solution and turnkey project.

Quality is our lifeline.

Hangji has a complete quality assurance system and an excellent quality management team. We insist on pre-production samples before mass production and final inspection and trial operation before shipment;

At the same time, we have obtained the international ISO, BV and SGS quality system certification.

We have officially settled in two B2B platforms (Alibaba, Made in China) and two official websites (wkd-rollingmill.com, hangjirollingmill.com).

The product graphic and video information displayed are all original by our company. Please pay attention to other platforms to avoid being cheated.

Since 1998, Hangji’s products and services have been exported to more than 20 countries and regions, such as China, Malaysia, Russia, Thailand, South Africa, India, Ethiopia, Philippines, Vietnam, Indonesia and so on.

Hangji has more than 60 customers and more than 100 production lines worldwide, such as Chandan (India), Ansteel (China), Johannesburg Steel (South Africa), Yuemei Steel (Vietnam) and so on.

Hangji’s factory is located at Xi’an Weikeduo Mechanical and Electrical Equipment Co., Ltd., No. 18, Jinggao South Road, Xi’an City, Shaanxi Province, China.

Warmly welcome customers at home and abroad to visit us! Please keep an eye on China’s COVID-19 policy or contact us to find out. We encourage our clients to prioritize online video conferencing to resolve issues.

Please tell us the following details by email or other means, so that we can recommend suitable plans and layouts to you:

Turnkey project or part of equipment or parts

Raw material (bill or scrap) and its size

Finished product and its dimensions

Whether a furnace is required and what fuel is used

Your planned annual output and working hours

Available factory area