From product solutions to the full line Solutions

Hangji provides you with complete tailor-made high speed wire rod and bar mill solutions including the latest technological solutions, comprehensive support, integration into existing mills and auxiliaries.

Case 1

High Speed RSM

We provided operational support for China Shaan Iron and Steel Group, offering online monitoring systems and localization services for its Morgan reducing and sizing mills. The RSM we manufactured has been awarded the Major Technology Prize in Shaanxi Province, China. It has also achieved a rolling speed of 110 meters per second while rolling 6mm at Guoxin Steel Company in Guangdong, China.

As of today, wire rod rolling in China is primarily arranged in an 8+2 configuration. The RSM has not only increased the speed but have also altered the rolling process by transitioning to hot rolling and resulting in lowered manganese (Mn) and vanadium-titanium indices.

Case 2

Tiangong International

Tiangong International Limited utilizes our specially customized high-line complete equipment with a small extension speed ratio (1.18). This has made it the sole company in China to establish a fully continuous rolling production line for both tool and die steel and titanium alloy rolling. The introduction of an S-shape bending and a coil diameter of 850mm is also a pioneering achievement in China. The successful rolling of titanium alloys has significantly contributed to achieving its target of a hundred billion yuan in output value.

Case 3

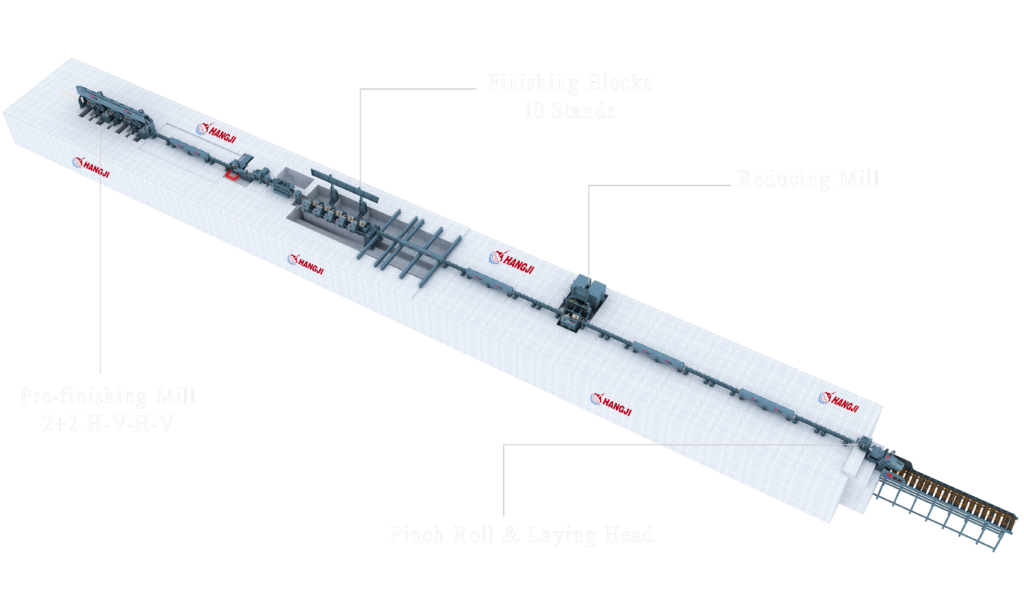

Special Steel Full Line

A special steel company in Guangxi, China, has fully adopted our company’s design featuring 28 stands of H&V no-pass-profile design (saving on rolls). Besides, 6 stands of pre-finishing mills and10 finishing blocks and the laying head area utilizes a flat design (reducing civil construction and factory investment).

Case 4

Double high speed wire rod line

In response to market demand, our reducing mill is applied in the double high speed wire rod lines at Guoxin Steel Company in Guangdong. This has increased the rolling speed to 100 meters per second. Additionally, we collaborated with SinoSteel to produce high-speed heavy duty reducing block mills. These blocks can be flexibly combined, leading to an increase in the rolling speed of rebar to 40 meters per second.

Case 5

thai international steel co., ltd.

The successful case of Thailand International Steel Company involves an annual production of 1.2 million tons on a dual high-speed bar production line, achieving a rolling speed of 40 meters per second. The production line is equipped with two stands of Φ285 pre-finishing mills and eight stands of Φ230 finishing blocks, complemented by a rotary drum cooling bed. The product specifications range from Φ9 to Φ27, catering to diverse market demands.

Case 6

Cost and investment savings

Yue Mei Steel Company has adopted our company’s turnkey wire rod and bar composite line, featuring a unique bending design, that effectively addresses the issue of limited factory space. This innovative solution not only resolves the challenge of space constraints but also allows for shared use of the bar line, resulting in significant cost savings. The implementation of this unique design reflects our expertise in engineering planning and solution provision.

Hangji: Leading the Industry with Innovative Special Steel Production Solutions

Hangji provided services for more than 80 production lines across China and stands as a premium supplier to prominent industry leaders such as China Baowu, Ansteel Group, MCC Group (Design Institute), Sinosteel Group, and Sinomach Group.

Notably, the majority of China’s stainless steel and special steel production lines utilize Hangji’s equipment, with clients including Haye Special Steel Co., Ltd., Jiangsu Fuda Special Steel Co., Ltd., Hubei Nantian Tool and Mold Technology Co., Ltd., Zhejiang Tianma Bearing Group Co., Ltd., Jiangsu Minglu Special Steel Group Co., Ltd., Tiangong International, Zhejiang Jiuli Special Materials Technology Co., Ltd., Suzhi Stainless Steel, CITIC Pacific Special Steel Co., Ltd., Zhaofeng Stainless Steel, India Chandan Stainless Steel, among others.

Distinguishing itself in the market, Hangji boasts a patented small extension finishing mill specifically designed for rolling stainless steel and special steel (Invention Patent Number: ZL.201420795399.2). This innovative technology allows Hangji to achieve the exceptional feat of rolling 304 stainless steel to a diameter as small as φ 4.5mm, a capability not matched by other manufacturers in the industry.

Projects Worldwide

High-Speed Wire Rod Mills | |

| Name | Project |

| Thailand Xinkeyuan Steel Co., Ltd. | 135m High-Speed Wire Rod and Bar Mill |

| Ethiopia Zhenzhen Steel Company | 135m High-Speed Wire Rod Mill |

| Yazd Industrial Constructional Steel Rolling Mill | 90m High-Speed Wire Rod Mill |

| India Chandan Steel Co., Ltd. | 135m High-Speed Wire Rod Mill |

| Indonesia Steel Co., Ltd. | 135m High-Speed Wire Rod and Bar Mill |

High-Speed Bar Mills | |

| Name | Project |

| Geili (Philippines) Machinery Co., Ltd | 135m High-Speed Bar Mill |

| Thailand Weichengfa Steel Co., Ltd | 135m High-Speed Bar Mill |

| India Sunvik Steels Pvt. Ltd | High-Speed Rebar Mill |

| Vietnam Steel Co., Ltd | 135m High-Speed Bar Mill |

| Kimia Saba Steel Company | 135m High-Speed Bar Mill |

Projects in China

High-Speed Wire Rod Mills | |

| Name | Project |

| Guangdong Daxing Steel Industry Co., Ltd | 135m High-Speed Wire Rod and Bar Mill |

| Hubei Nantian Tool and Mold Technology Co., Ltd. | Special Steel Wire Rod Mill |

| Fujian Sangang (Group) Co., Ltd | High Speed Wire Rod Mill |

| Nantong Kangrui New Materials Co., Ltd | Turnkey Project |

| SinoSteel | High Speed Finishing Blocks |

High-Speed Bar Mills | |

| Name | Project |

| Guangdong Huafeng Steel Co., Ltd | 135m High-Speed Wire Rod and Bar Mill |

| Fujian Wu Hang Steel Co., Ltd | Special Steel Wire Rod Mill |

| SinoSteel Nuotai Hongda Project | High Speed Wire Rod Mill |

| Guangxi Shenglong Co., Ltd | High Speed Wire Rod Mill |

| Wuzhou Yongda Special Steel Co., Ltd. | Wire Rod Mill |