HANGJI proudly announces our comprehensive maintenance service for the SMS production line at a Chinese steel plant. As a professional rolling mill manufacturer, we are committed to delivering top-notch services not only for our own equipment but also for other brands.

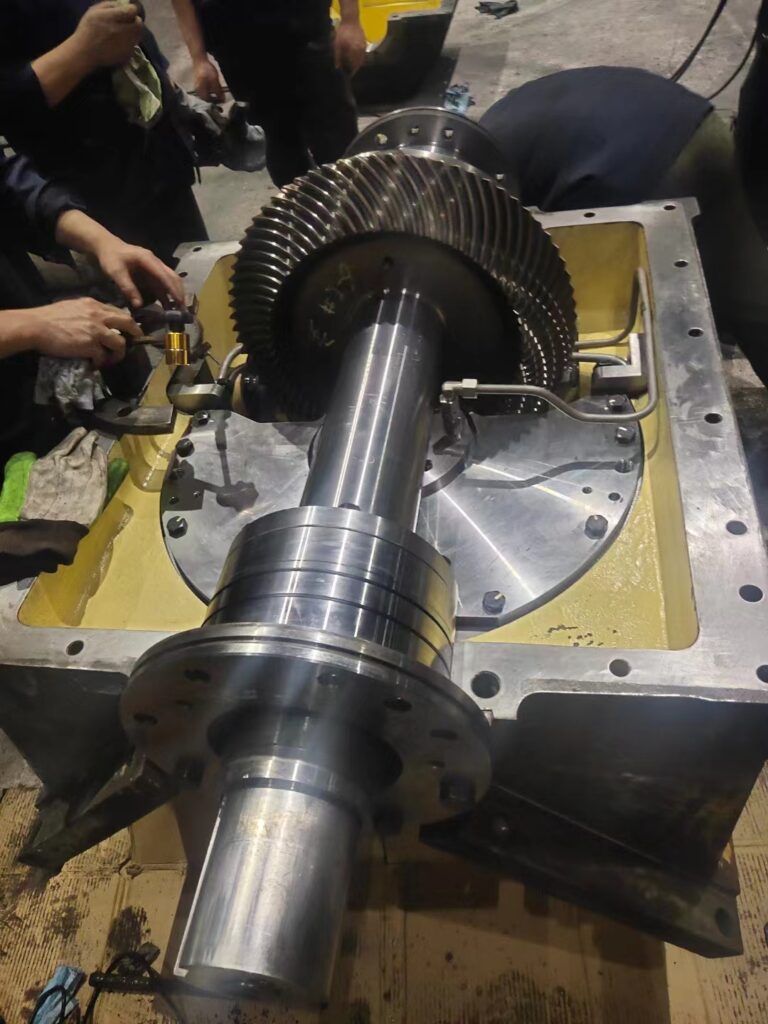

In this maintenance service, our professional team meticulously maintained the bevel gearbox and roller box of the SMS finishing blocks. The bevel gearbox, a critical component in the production line, directly affects the efficiency of the entire line’s operation. We not only performed maintenance but also replaced bearings and other necessary parts to ensure smooth operation. Additionally, we conducted thorough inspections and commissioning of the roller box to ensure its stability and reliability during the production process.

In addition to maintenance and parts replacement, our technical team conducted commissioning work to ensure the coordinated operation of all components of the production line. Through precise calibration and optimization, we maximized the operational efficiency of the production line.

To ensure the comprehensiveness and quality of the maintenance service, we conducted oil testing, vibration measurement, and comprehensive checks of finishing block sound and temperature. Through these rigorous testing measures, we ensured the safety and stability of the equipment, providing reliable production support to our customers.

Throughout the entire service process, we always prioritized customer needs, providing personalized and comprehensive solutions. Whether it’s equipment maintenance, parts replacement, or commissioning work, we provided satisfactory services with professionalism and efficiency. We understand that after-sales service is not just about repairing and maintaining equipment but also about repaying customer trust and support.