No-Twist Mill

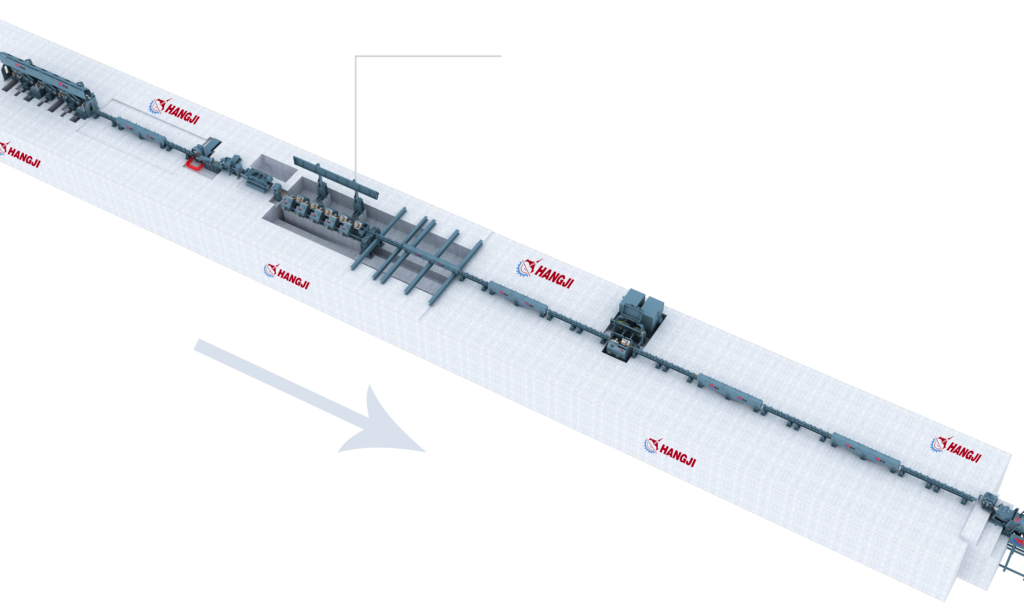

The heavy-duty 45° top-crossing no-twist block mills will be arranged in the high-speed wire rod and bar production line workshop.

Through the continuous micro-tension rolling of the multi stands of finishing block mills, the rolled material of Ø17~Ø21mm from the upstream will be rolled into final Ø5.5 mm minimum wire rod or Ø8 mm rebar.

ADVANTAGES OF NO TWIST MILL

• Roll at 110m/s max for high productivity

• Improve dimensional accuracy

• Convenient for commissioning and start-up

• Lower maintenance cost

• Reduce roll change time

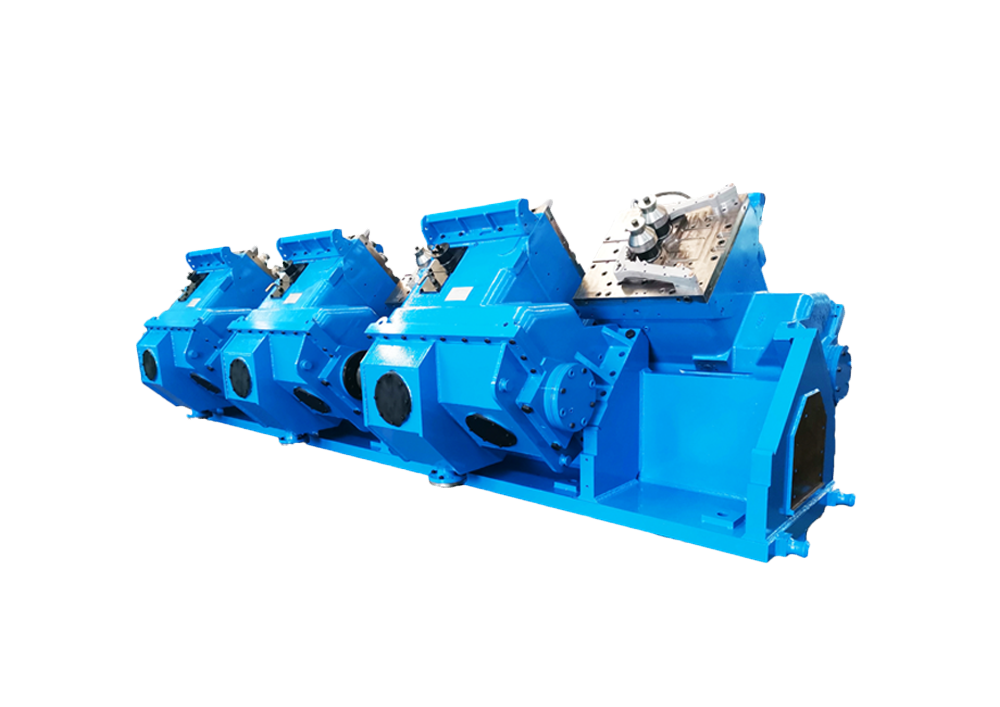

HIGH SPEED FINISHING BLOCK MILL |

|

230 BLOCK MILL (OIL FILM BEARING TYPE) |

SUITS HIGH SPEED CARBON STEEL WIRE ROD MILL |

| 230 BLOCK MILL SMALL ELONGATION (OIL FILM BEARING TYPE) | SUITS ALLOY AND Non-ferrous WIRE ROD MILL |

| 260 BLOCK MILL SMALL ELONGATION (ROLLING BEARING TYPE) | SUITS LOW SPEED ALLOY AND Non-ferrous WIRE ROD MILL |

| 320 BLOCK MILL SMALL ELONGATION (ROLLING BEARING TYPE) | SUITS LOW SPEED ALLOY AND Non-ferrous WIRE ROD BAR MILL |

Application

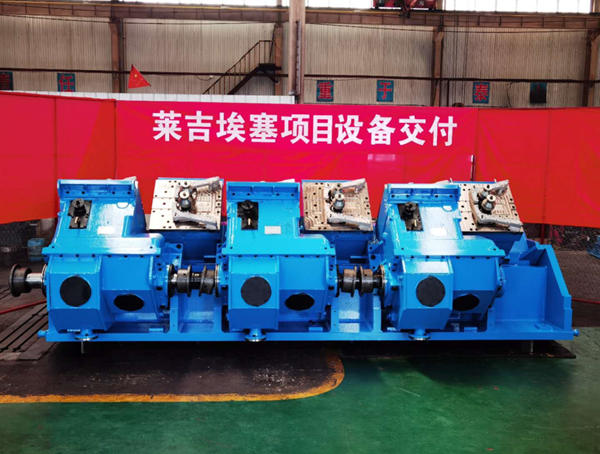

The finishing blocks are widely utilized in major steel plants worldwide, including Ansteel Group, Chandan Steel, Yazd Factory, Sinosteel, and Sunvik TMT etc.

Old Generation Display

important things you should know

Questions And Answers

Please provide the following details via Email or WhatsApp so that we can offer suitable solutions and layouts for your project:

1. Project Scope:

Is it new project or renovation project?

2. Raw Material:

Type of raw material (billets or scrap) and its size?

3. Finished Product:

Type of final product (wire rod or bar) and its size?

4. Production Scale:

Your planned annual output in tons?

5. Factory Space:

Available factory size (width and length) for the project?

We are a professional wire rod and bar rolling mill equipment manufacturer with 26 years of experience.

Hangji boasts a comprehensive quality assurance system along with an exceptional quality management team. We adhere to the practice of conducting final inspections and trial operations before shipment.

Simultaneously, we have obtained international certifications for quality systems, including ISO, BV, and SGS.

We have officially established our presence on two B2B platforms (Alibaba, Made-in-China) and operate through two official websites (hangjirollingmill.com, xawkd.com).

Hangji’s factory is located at Xi’an Weikeduo Electrical and Mechanical Equipment Co., Ltd., No. 18, Jinggao South Road, Xi’an City, Shaanxi Province, China.

Explore our factory through the following links:

YouTube:

Factory Video

Google Map:

We extend a warm welcome to customers from both domestic and international markets to visit us.

Since 1998, Hangji has been exporting its products and services to over 20 countries and regions, including but not limited to China, Malaysia, Russia, Thailand, South Africa, India, Ethiopia, the Philippines, Vietnam, Indonesia, and more.

Globally, Hangji has successfully completed over 100 wire rod and bar production lines. Notable clients include Ansteel (China), SinoSteel(China), Yazd Factory (Middle East), Chandan (India), among others.