The function of flying shear is to cut the rolled pieces running on the production line according to the set length. Flying shear is fast in action, high in accuracy and compact in structure. It is installed on the rolling line of continuous rolling mill and widely used in modern rolling workshops. It is one of the key equipment of modern continuous rolling production line.

According to the requirements of the production process, a flying shear is usually arranged in the rough rolling area, the intermediate rolling area, the finishing rolling area and the collecting area of the rolling line, respectively for head cutting, tail cutting, accident breaking, multiple and sizing. The flying shear is characterized by being able to cut the rolling piece in motion transversely.

The basic requirements for it are:

- The production capacity of the flying shear must be coordinated with the productivity of the rolling mill to ensure that the productivity of the rolling mill can be brought into full play.

- During shearing, the partial speed of the shear blade in the moving direction of the rolled piece shall keep a certain relationship with the moving speed of the rolled piece to ensure that the rolled piece will not be bent or broken during shearing.

- Shear length according to rolling process to make the length dimension tolerance and shear section conform to relevant national regulations.

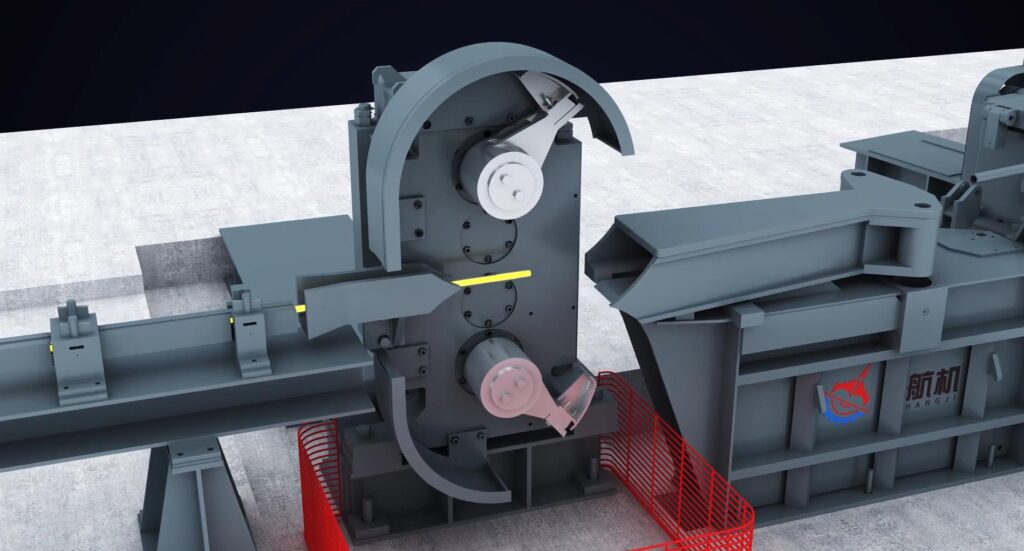

There are many forms of flying shear, such as crank connecting rod flying shear, rotary flying shear, combined flying shear, disc flying shear, pendulum flying shear, etc. See shearing machines right now.